Reimagining Carbon

We use in-house biochemical and electrochemical methods processes to transform carbon

NuFood: Food Waste Valorisation

We begin by processing mixed food waste, first screening to remove all inorganic materials. The remaining organic matter is then blended to unlock valuable macronutrients such as proteins and carbohydrates. Through a biotransformation process, these are converted into bioethanol. This ethanol is purified using our proprietary distillation and adsorption system. Our approach ensures zero waste: the water-rich slurry is ideal for use as a liquid organic fertilizer, the solids make excellent compost, and the oils can be burned on-site for energy or converted into biodiesel.

Key figures per ton of food waste

-

1 ton CO2e mitigated

-

1 ton of waste saved from land

-

50 - 100 L Bioethanol

-

50 - 120 kg Compost (dry basis)

-

40 - 200 L Liquid Organic Fertilizer

-

300 - 500 L Treated Water

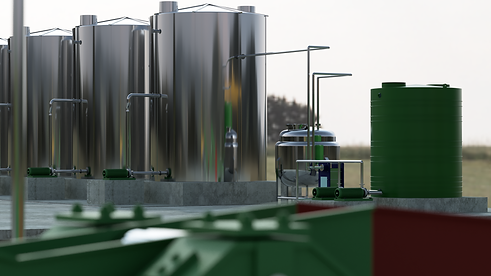

NuCane: Sugarcane Biorefineries

Bioethanol from sugarcane is a global powerhouse industry, led by countries like Brazil and Australia. At NuCarbon, we didn’t reinvent the wheel—we revolutionized it, making it lighter, faster, and more efficient. Our proprietary fermentation, distillation, and process integration technologies have redefined bioethanol production, enabling unparalleled efficiency at commercial scales up to 10 times smaller than previously deemed possible. These innovations not only reduce production costs but also outperform traditional methods using molasses, sorghum, sugar beet, or grains.

Key figures per ton of sugarcane

-

1.1 ton CO2e mitigated

-

70 - 100 L Bioethanol

-

60 - 80 kg 99.9% CO2

-

80 - 100 L Liquid Organic Fertilizer

-

10 - 20 kg High protein feed

NuCapture: Carbon Capture and Conversion

Harnessing the natural carbon cycles found in nature, we have developed an alkali-based Direct Air Capture (DAC) system designed to extract carbon dioxide from the atmosphere and concentrate it for further applications. Additionally, we have synthesized advanced copper-based catalysts capable of simultaneously regenerating the alkali and converting captured carbon dioxide into valuable compounds like ethylene, methanol, ethanol, and other carbon-rich products. While the system is still under development, we anticipate full integration with our NEXUS platform by 2027.

Key estimates per ton of CO2

-

1000 - 1500 kWh input

-

25 - 50% Overall Energy Efficiency

-

400 - 500 kg Total products

-

~250 L Ethanol